The new metal forming system for

above grade concrete flatwork to be

used in conjunction with metal decking

| Installation | ||||||||||||||||||||||

| After placement of metal decking, secure

KEY-DECK® supports by attaching with sheet metal screws. Adjust KEY-DECK® supports at both ends of pour to finished floor elevation. (If using vinyl cap, adjust supports 3/16” lower.) Stretch string line over entire length of pour and adjust remaining KEY-DECK® supports to finished floor elevation. Use five KEY-DECK® supports per 10’ section of KEY-LOC® joint. Hang joint on supports and push downward. To insure perfect joint alignment, snap-in splice at joint ends. Pour against keyway side of joint first. CONTACT THE ARCHITECT OR ENGINEER IN CHARGE OF THE PROJECT CONCERNING PLACEMENT OF THIS PRODUCT. |

|

|||||||||||||||||||||

| Material | SPECIFICATIONS | |||||||||||||||||||||

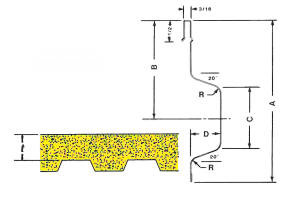

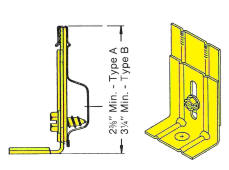

| KEY-LOC® Joint is manufactured from 24 gauge galvanized steel. It is furnished in 10’ lengths for 2 1/2” to 4” slabs. KEY-DECK® Supports are manufactured from 14 gauge galvanized steel and are available in two sizes which adjust to accommodate 2 1/2” to 4” slabs. |

|

|

|

| SPLICE | |

|

TYPE A -Measures 2 3/8”, will expand to 3 3/8”. Use Type A supports for 2 1/2” to 3” slabs. |

|

|

TYPE B -Measures 3 1/4”, will expand to 4 3/16”. Use Type A supports for 3 1/2” to 4” slabs. |

|

|

|

| FORM-A-KEY PRODUCTS IS NOT RESPONSIBLE FOR

STRUCTURAL FAILURE DUE TO PLACEMENT OF THIS PRODUCT. CONTACT THE PROJECT ENGINEER OR ARCHITECT BEFORE USING. |

|